Table of Contents

Introduction

Foreign executives often approach Chinese manufacturers through a transactional lens — chasing cost savings, comparing hourly rates, and negotiating the lowest price. Although cost matters, that perspective misses the deeper reality of why China leads in manufacturing, even as labor costs rise and global supply chains shift.

The true strengths of Chinese manufacturing go far beyond cost. They lie in speed, adaptability, and problem-solving under pressure — qualities refined through decades of fierce competition and tight delivery expectations.

Our 5 Key Lessons from Running a China Joint Venture and Common Mistakes Foreign Companies Make in Chinese Joint Ventures highlight some pitfalls to avoid, but in this article, we want to explore the strengths of Chinese manufacturers — and what global companies can learn from them.

1. Speed and Responsiveness – Why China Leads in Manufacturing

Perhaps the most visible advantage of why China leads in manufacturing is sheer speed. Product ideas move from design to prototype to production at a pace that often surprises Western companies. The ability to mobilize resources quickly — materials, labor, and tooling — reflects an ingrained responsiveness to customer needs.

Where many Western cultures value creativity, design, and in-depth planning and analysis, Chinese culture abounds in just moving forward. It is often an iterative approach, with frequent sampling, and can appear to Western managers that there is a lack of understanding of the project requirements. That beguiles a hidden advantage of Chinese manufacturers – speed at developing and improving their products.

For foreign partners, this agility means projects can be adjusted, scaled, or relaunched without the long approval cycles common in corporate environments. The Chinese cultural emphasis on “making it happen” enables timelines that would be impossible elsewhere, provided the foreign side communicates goals clearly and maintains close collaboration. During the early days of Covid, China built an entire, functional single floor hospital with 1,000 beds to treat patients in an astonishing 11 days. When motivated, focused, and directed, no one can beat the speed at which China can deploy new production.

China’s manufacturing speed is rarely about urgency — it’s usually the result of deep alignment happening before execution ever becomes visible.

2. Deep Supplier Ecosystems

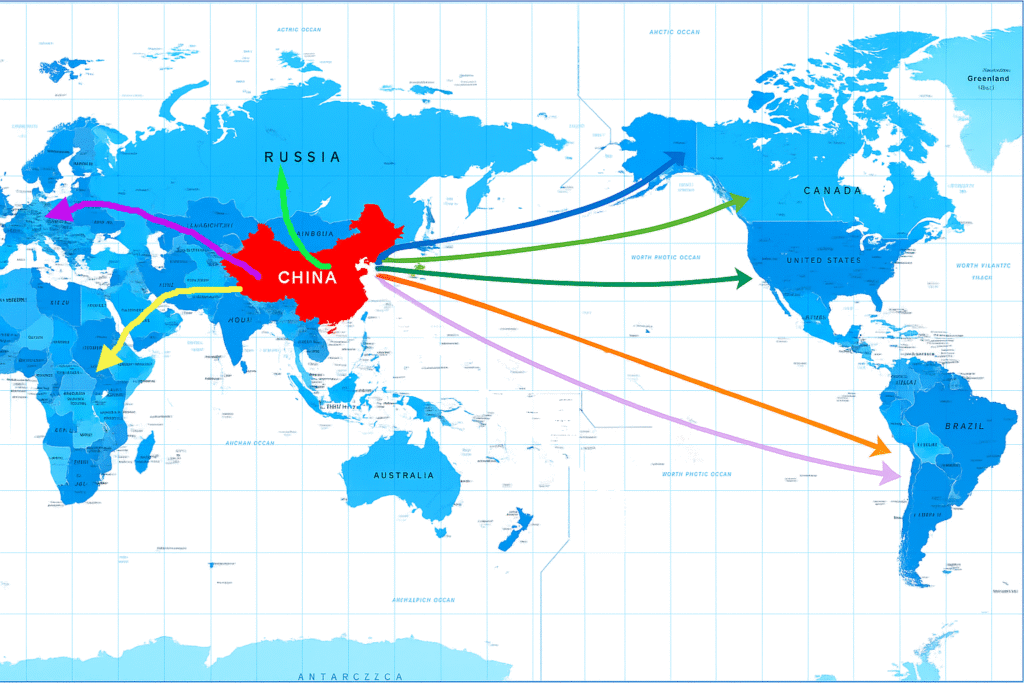

Manufacturing hubs such as the Yangtze River Delta, Pearl River Delta, and the greater Chongqing region represent dense industrial ecosystems where nearly every component or service can be sourced within a short radius. Suppliers know each other, share subcontractors, and can coordinate informally to solve problems fast. (China Briefing)

This interconnectedness creates a form of network intelligence: if one supplier faces a bottleneck, another can be found overnight. For joint ventures and OEM partners, this ecosystem becomes a built-in advantage — offering flexibility that’s difficult to replicate in more fragmented markets.

Although companies will not disclose trade secrets easily, there is a more open market in China for some information – both market related and technical deployment – than in many Western countries. Therefore, information is more widespread and available for both problem solving, but also for market precision and penetration. For example, it is quite common for most product selling prices to be readily available and disclosed, compared to the West where protecting your purchase price might be considered a competitive advantage.

3. Commitment to Continuous Improvement

While Western factories often emphasize formal quality programs, Chinese teams tend to approach improvement in a pragmatic and iterative way. Many managers take pride in solving yesterday’s problem today — not through paperwork, but through direct observation and quick experimentation.

True strengths of China manufacturing … speed, adaptability, and problem solving …

This culture of “learning by doing” produces steady gains in efficiency and quality, particularly when supported by constructive feedback from the foreign partner. Encouraging joint problem-solving, rather than simply enforcing compliance, taps into this improvement mindset and builds mutual respect.

Many global companies have seen this in action – an initial product or offering from China could very well be inferior in certain performance aspects. But it is unwise to stop the development work because Chinese manufacturers quickly respond with the next improvement and respond to complaints with tenacity and speed.

4. Pragmatic Problem-Solving Under Pressure

Every manufacturing partnership faces challenges — late shipments, raw material changes, or unexpected technical issues. Chinese managers are typically resourceful and solutions-oriented, focusing on how to fix the problem rather than who caused it. This attitude stems from both competitive necessity and a deep cultural bias toward maintaining harmony.

The result is an ability to adapt rapidly under uncertainty. Foreign companies that recognize this strength — and avoid micromanaging or assigning blame — often find that crises become opportunities to strengthen trust and refine processes. It is another trait of why China leads in manufacturing.

5. Saving Face

It is deeply engrained in Chinese culture the need to save face –liu mianzi. It is an extremely important aspect of social honor and prestige, and is prevalent heavily in both government and commercial business. It is important for companies and especially joint venture partnerships to understand this need from their Chinese partners for a couple of reasons. This article from World Bank explores this further.

First, it is sometimes noted that Chinese people and companies are very slow to respond with bad news – and in fact will often go silent when pressed for some information that is considered unpleasant or a failure. This silence is not, as is often attributed, a lack of ownership or responsibility. What is typically at play is the other party is in fact desperately trying to find a solution and reply with a positive path forward. Where western culture espouses openness in the face of trouble to better prepare and plan a response, the Chinese culture is to safe face and offer the solution rather than only be the bearer of bad news.

Second, it is very important for joint venture companies to understand this cultural requirement so as to not back their partner into a corner and awkward situation. Instead, it is best to approach the situation or conflict understanding that their partner wants to offer a solution and will need some space to finalize what that looks like. Avoid putting the Chinese partner into a position where they can not emerge with respect and dignity; the result will be more rigid and a less-than-optimal path forward.

6. Relationship Loyalty and Flexibility

When trust has been established, Chinese partners often display remarkable flexibility — absorbing short-term costs, re-allocating labor, or working overtime to protect the partnership. This loyalty is built through consistent communication, respect, and personal rapport, not just contracts.

In practice, this means that even in turbulent conditions, a partner who believes the relationship is mutually beneficial will go to great lengths to preserve it. Western managers who take time to understand guanxi — the relational foundation of Chinese business — often gain resilience that formal agreements alone cannot guarantee.

Conclusion

The enduring strength of Chinese manufacturing is not just in cost competitiveness but in its ability to deliver speed, adaptability, and reliability through relationships. Western firms that see Chinese partners as extensions of their strategic network — rather than as low-cost vendors — unlock far greater value.

The question of why China leads in manufacturing is answered by these enduring strengths — speed, adaptability, supplier depth, cultural understanding, and relationship loyalty. Building on these qualities requires openness, patience, and respect for how business truly operates on the ground in China. When those principles align, a manufacturing partnership can evolve into one of the most resilient and productive relationships in global industry.

For additional insights on Chinese manufacturing strengths, see 13 Steps to Manufacturing in China by Bruce Mitchell, also listed on our Joint Ventures China Resources page.

Frequently Asked Questions

To help readers understand the deeper forces behind China’s manufacturing leadership, here are answers to the most common questions people ask:

1. Why is China the world leader in manufacturing?

China leads in manufacturing because it combines massive scale, integrated supply chains, government support, and a workforce skilled in rapid execution. These factors allow companies to move faster, produce at lower cost, and respond to global demand with unmatched speed.

2. How do China’s supply chains give it an advantage?

China’s supply chains are hyper-concentrated—components, tooling, raw materials, and skilled labor often exist within the same region. This reduces delays, lowers logistics costs, speeds up iteration, and allows companies to pivot production extremely quickly.

3. Why are Chinese factories able to scale production so quickly?

China can scale quickly because factories, suppliers, and local governments coordinate resources fast. Hiring, tooling, production lines, and logistics can be mobilized in days or weeks, not months. This responsiveness is a core competitive advantage for Chinese manufacturers.

4. Is China’s speed in manufacturing sustainable long-term?

Yes—China continues to invest in automation, robotics, and advanced materials while expanding domestic demand and upskilling workers. Although costs are rising, the country’s manufacturing ecosystems remain stronger and faster than those in most other global regions.

Enjoying this?

Get weekly, real-world insights on China joint ventures and China manufacturing.